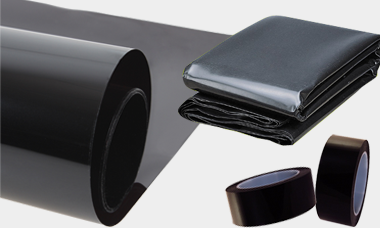

Low Density Polyethylene (LDPE) sheets are extensively used for protection of liquid contamination, agricultural, industry, industrial projects. LDPE film act as a perfect line to prevent foreign material entering through ground water source as well as prevent seepage loss in water conservation projects.

Low Density Polyethylene (LDPE) sheets are extensively used for protection of liquid contamination, agricultural, industry, industrial projects. LDPE film act as a perfect line to prevent foreign material entering through ground water source as well as prevent seepage loss in water conservation projects.

Other Applications :

- Agriculture

- Lining of Canal, reservoir, ponds

- Lining of industrial effluent plant

- Tunnels

- Packaging and wrapping

- Water roofing for terrace gardens

- For protection of food grains, fertilizers, cotton, chemicals, cement, Contractions and power plants

- Concrete road and bridge

- Steel plants etc.

Properties of LDPE :

- LDPE film has excellent mechanical properties.

- Saves water seepage upto 60% of total quality of water available.

- It has a very low moisture / vapour transmission rate.

- Very good resistance against chemical and unaffected by bacterial or fungal growth.

- Very good resistance against ozone, oxidation, weather & water because polyethylene has a long chain of hydrocarbon which gives above properties.

LDPE is soft, low barrier, good clarity film. It is also the least expensive of all polymer packaging films. It is possible to alter basic properties of LDPE film by blending other polymers and/or additives, like EVA, LLDPE, Color Pigments, Black Carbon etc. to meet your specific application.

Very flexible, natural milky color, translucent with high impact strength. Excellent for mild and strong buffers, good chemical resistance. Good water vapor and alcohol barrier properties. Poor gas barrier, sterilizable with EtO or gamma radiation. Good stress crack and impact resistance.

Typical LDPE Film Applications :

- Food packaging (bread bags, baked goods, light duty produce bags, etc.)

- Light to Heavy duty bags

- Textile packaging (shirts, sweaters, etc.)

- Packaging applications requiring excellent clarity.

- Special applications (Tent windows for military use)